SR-GRADE

SR compounds are versatile materials based on styrenebutadiene-styrene (SBS) block copolymers. It has elastomeric properties, flexibility and high strength. SR compounds have high resistance to water, acids and bases soaking in hydrocarbon solvent and oils will deteriorate. SR compound react the same as other easy molding thermoplastics with comparable melt flow.

| Characteristics | Application |

|---|---|

|

|

| GRADE | Test Item | Test Metod | Unit | H70 | H40 |

|---|---|---|---|---|---|

| SR-8000 | Hardness | ASTM D 2240 | Shore A | 70±3 | 40±3 |

| Specific Gravity | ASTM D 792 | 1.00 | 1.00 | ||

| Tensile Strength | ASTM D 1457 | Kg/crff | 57 | 47 | |

| Elongatoin | ASTM D 1457 | 390 | 570 | ||

| SR-8800 | Hardness | ASTM D 2240 | Shore A | 68 ± 3 | 40±3 |

| Specific Gravity | ASTM D 792 | 0.94 | 0.91 | ||

| Tensile Strength | ASTM D 1457 | Kg/cnr | 72 | 55 | |

| Elongatoin | ASTM D 1457 | 870 | 920 | ||

TPE

ER-GRADE

ER series are engineering thermoplastic elastomer compound which based on Styrene-Ethylene-ButyleneStyrene (SEBS) block co-polymer that higher temperature, chemical resistance, heat stability, and weather-ability than SR series. ER series can be seen in the numerous processing techniques in which it is need injection molding, blown molding, compression molding, and extrusion molding.

| Characteristics | Application |

|---|---|

|

|

| GRADE | Test Item | Test Metod | Unit | H70 | H40 |

|---|---|---|---|---|---|

| ER-7000 | Hardness | ASTM D 2240 | Shore A | 70±3 | 30±3 |

| Specific Gravity | ASTM D 792 | 0.92 | 0.95 | ||

| Tensile Strength | ASTM D 1457 | Kg/crff | 75 | 30 | |

| Elongatoin | ASTM D 1457 | 700 | 820 | ||

| ER-7000 | Hardness | ASTM D 2240 | Shore A | 40 ± 3 | 60±3 |

| Specific Gravity | ASTM D 792 | 0.88 | 0.89 | ||

| Tensile Strength | ASTM D 1457 | Kg/cnr | 70 | 60 | |

| Elongatoin | ASTM D 1457 | 980 | 750 | ||

TPV

TPV-GRADE

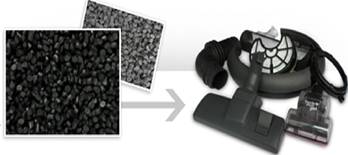

TPV is a product that is already completely cross-linked an d there is no need for an extra cross-link process before its ultimate use. Also, it is possible to simplify the processes a nd reduce the prime cost as it is an environment-friendly m aterial allowing for an easy recycle of scraps resulted from processing.

| Characteristics | Application |

|---|---|

|

Automobile : Tuning, gasket, door gap closer, interior material, tube and windshield space etc. Office equipment : Vibration isolation material, feed roller and computer pit etc. House equipment : Hose connector, door gap closer, interior and exterior material hose, gasket, motor mount, lever peak, Electric equipment : Power transmitter/receiver, connector, mine cable, control cable, coil cord and power circuit cable etc. |

| GRADE | Test Item | Test Metod | Unit | H45 | H65 | H75 |

|---|---|---|---|---|---|---|

| Hardness | ASTM D 2240 | Shore A | 55±3 | 65±3 | 75±3 | |

| Specific Gravity | ASTM D 792 | 0.98 | 0.96 | 0.96 | ||

| Tensile Strength | ASTM D 1457 | Kg/crff | 40 | 65 | 80 | |

| Elongatoin | ASTM D 1457 | 750 | 650 | 680 |

Certificate of Analysis

Certificate of Analysis